All Images

News Release 04-053

Yet Another Benefit of Green Tea

New, biodegradable machining compound is more effective than industry standards

This material is available primarily for archival purposes. Telephone numbers or other contact information may be out of date; please see current contact information at media contacts.

Dr. John Lombardi of Ventana Research holding a separator funnel containing the company’s environmentally friendly fluid used in ceramic polishing.

Credit: Erica von Koerber, Evon Photography (Tucson, Ariz.)

Download the high-resolution JPG version of the image. (232 KB)

Use your mouse to right-click (Mac users may need to Ctrl-click) the link above and choose the option that will save the file or target to your computer.

A separator funnel containing Ventana's machining fluid.

Credit: Erica von Koerber, Evon Photography (Tucson, Ariz.)

Download the high-resolution JPG version of the image. (170 KB)

Use your mouse to right-click (Mac users may need to Ctrl-click) the link above and choose the option that will save the file or target to your computer.

The machine used by Ventana Research for evaluating fluids during the Phase I SBIR program. The researchers mount computer hard drive read-write heads in the brass T-shaped attachment on the right side of the machine. Weights apply pressure to the "T" and to the read-write head specimen. The researchers measure the sample weight change before and after.

Credit: Erica von Koerber, Evon Photography (Tucson, Ariz.)

Download the high-resolution JPG version of the image. (387 KB)

Use your mouse to right-click (Mac users may need to Ctrl-click) the link above and choose the option that will save the file or target to your computer.

A close-up of the machine in action. The dark brown rings on the rotating abrasive wheel are from the "lapping swarf." The swarf is a mixture of the Ventana fluid and ceramic debris particles from the read-write head specimen. During the process, the researchers add the Ventana fluid drop by drop onto the rotating wheel. Centripetal acceleration causes the swarf to move to the outer edge of the rotating wheel.

Credit: Erica von Koerber, Evon Photography (Tucson, Ariz.)

Download the high-resolution JPG version of the image. (542 KB)

Use your mouse to right-click (Mac users may need to Ctrl-click) the link above and choose the option that will save the file or target to your computer.

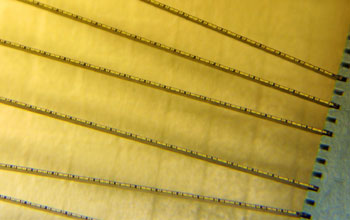

A side view of six polished ceramic read-write heads assembled in a holding tray. Note the metallization on the edges of the bars. The ceramic material itself is black.

Credit: Erica von Koerber, Evon Photography (Tucson, Ariz.)

Download the high-resolution JPG version of the image. (193 KB)

Use your mouse to right-click (Mac users may need to Ctrl-click) the link above and choose the option that will save the file or target to your computer.

The investigators responsible for the environmentally friendly fluid who were supported by an NSF Phase I SBIR grant. From left: Dr. Donald Zipperian (Pace Technologies, Tucson, Ariz.), Dr. John Lombardi (Principal Investigator, Ventana Research Company, Tucson, Ariz.) and Prof. Srini Raghavan (University of Arizona, Materials Science and Engineering Department, Tucson, Ariz.).

Credit: Erica von Koerber, Evon Photography (Tucson, Ariz.)

Download the high-resolution JPG version of the image. (407 KB)

Use your mouse to right-click (Mac users may need to Ctrl-click) the link above and choose the option that will save the file or target to your computer.

View Video

In this movie, the ceramic read-write heads are loaded into a holding tray and mounted on the polishing machine. The heads are then lowered for the polishing process, during which the Ventana fluid is added drop by drop onto the rotating wheel. Centripetal acceleration causes the fluid and debris to move to the outer edge of the rotating wheel.

Credit: Ventana Research

View Video

Download video (filesize: 4.3MB). In this movie, the ceramic read-write heads are loaded into a holding tray and mounted on the polishing machine. The heads are then lowered for the polishing process, during which the Ventana fluid is added drop by drop onto the rotating wheel. Centripetal acceleration causes the fluid and debris to move to the outer edge of the rotating wheel.

Credit: Ventana Research