News Release 05-150

A New Technique for High-Precision Nanomanufacturing

August 25, 2005

This material is available primarily for archival purposes. Telephone numbers or other contact information may be out of date; please see current contact information at media contacts.

Researchers at Pennsylvania State University have demonstrated a new technique for nano-manufacturing that could make it significantly easier to create high-precision components for nanoscale electronics, sensing devices and the like.

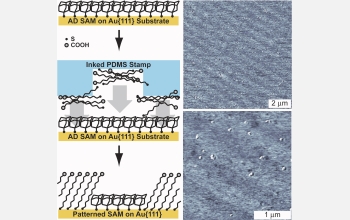

Known as microdisplacement printing, the new technique is based on a widely used patterning method known as microcontact printing--a simple way of fabricating chemical patterns that does not require clean rooms and other kinds of special and expensive environments.

Both methods involve "inking" a patterned rubber-like stamp with a solution of molecules, then applying the inked stamp to a surface. "But the new microdisplacement technique gives us more control over the precision with which the patterns are placed and retained, and also allows us to use a wider range of molecules," says principal investigator Paul Weiss.

Weiss and his colleagues were funded in part by the National Science Foundation, and will describe their new technique in the 14 September issue of the journal Nano Letters.

For more information, see the Penn State news release.

-NSF-

Media Contacts

Barbara Kennedy, Pennsylvania State University, (814) 863-4682, email: science@psu.edu

M. Mitchell Waldrop, NSF, (703) 292-7752, email: mwaldrop@nsf.gov

Principal Investigators

Paul Weiss, Pennsylvania State University, (814) 865-3693, email: stm@psu.edu

Related Websites

The Weiss laboratory: http://stm1.chem.psu.edu/

The Penn State news release: http://www.science.psu.edu/alert/Weiss8-2005.htm

The U.S. National Science Foundation propels the nation forward by advancing fundamental research in all fields of science and engineering. NSF supports research and people by providing facilities, instruments and funding to support their ingenuity and sustain the U.S. as a global leader in research and innovation. With a fiscal year 2023 budget of $9.5 billion, NSF funds reach all 50 states through grants to nearly 2,000 colleges, universities and institutions. Each year, NSF receives more than 40,000 competitive proposals and makes about 11,000 new awards. Those awards include support for cooperative research with industry, Arctic and Antarctic research and operations, and U.S. participation in international scientific efforts.

Connect with us online

NSF website: nsf.gov

NSF News: nsf.gov/news

For News Media: nsf.gov/news/newsroom

Statistics: nsf.gov/statistics/

Awards database: nsf.gov/awardsearch/

Follow us on social

Twitter: twitter.com/NSF

Facebook: facebook.com/US.NSF

Instagram: instagram.com/nsfgov