Center for Wireless Integrated MicroSystems

The University of Michigan (lead institution)

![]()

Integrated microsystems for widely-distributed information gathering and control

| A National Science Foundation Engineering Research Center since 2000 |

![]()

|

Partner Institutions:

|

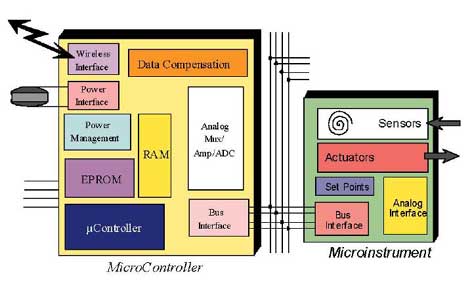

This Engineering Research Center is focused on miniature low-cost integrated microsystems capable of measuring (or controlling) a variety of physical parameters, interpreting the data, and communicating with a host system over a bi-directional wireless link. As such, the Center addresses the intersection of microelectronics, wireless communications, and microelectromechanical systems (MEMS). The resulting devices are expected to become pervasive in society during the next two decades, extending the electronic connectivity now represented by personal communications and the worldwide web to information provided directly by (or supplied to) the environment. Such systems will provide button-sized information-gathering nodes for applications ranging from environmental monitoring (weather, global change, air and water quality) to improved health care (wearable and implantable biomedical systems). They will consist of a power source, software, an embedded micro-controller, a hardwired or wireless interface to the external world, and front-end microinstruments selected for the intended application. Operating at less than 100µW, they will occupy volumes as small as 1cc and communicate over distances from a few inches to a few miles.

Research

|

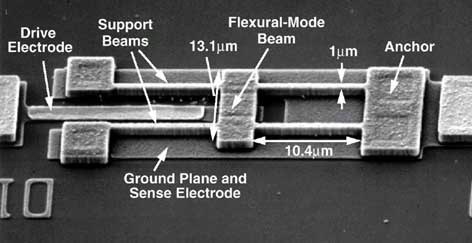

| A 92MHz micromechanical filter: negligible power in very little space. |

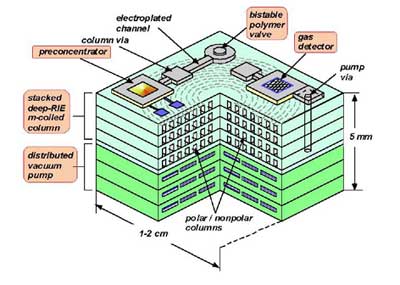

Center research is organized in four thrusts, dealing with micropower circuits, wireless interfaces, sensors and microinstruments, and micropackaging. These efforts are extending existing micropower circuit techniques and sensor-driven controller architectures, developing single-chip communication transceivers based on micromechanics, exploring a variety of self-testing microinstruments (including chemical, mechanical, and thermal devices), and developing hermetic wafer-level packaging using deposited thin films and vacuum-sealed cavities. The goal is to develop systems that are rapidly configurable, reconfigurable, and self-testing and to define their fundamental limits in the face of conflicting constraints imposed by power sources, process technology, circuit limits, wireless power-range tradeoffs, and size. The thrusts are being coordinated by focusing them on two application testbed systems: an rf-powered implantable microsystem (initially a cochlear prosthesis for the profoundly deaf, with subsequent extension to devices for treating epilepsy and Parkinson's disease); and a battery-powered environmental monitoring system capable of gas analysis as well as the measurement of barometric pressure, temperature, humidity, and other variables. Each of these testbeds is aimed at achieving a significant breakthrough in its own right while emphasizing the challenges that will be found in microsystems generally.

The size, range, and operating lifetime of wireless microsystems are strongly dependent on the power sources required to run them. While batteries are slowly improving, substantial improvements in system performance appear possible through lower-power circuit techniques that may also make the use of renewable energy sources (e.g., solar) viable. Efforts are focusing on the use of low-voltage deep-submicron technology to achieve high functionality at very low power. The challenges are not only in low-voltage mixed-signal circuits but also in areas such as self-test, noise suppression, active power management, and digital sensor compensation. The use of in-module data interpretation (increasing power dissipation in the controller) must be weighed against the power required for wireless data transmission. The fundamental power-range requirements must also be better understood, taking advantage of MEMS-based antenna structures and micropower MEMS resonators for filtering and frequency conversion.

|

| Architecture for a wireless integrated microsystem. |

In the neural prosthesis testbed, flexible electrode arrays containing site-selection electronics are being developed along with active measurement and control of array position in the cochlea. Subsequent efforts will address the development of fully implantable microsystems capable of electrically recording neural activity and precisely delivering electrical and chemical stimuli at the cellular level to address neurological disorders at point of need. The centerpiece of the initial environmental system is an integrated gas chromatography system operating at 1mW in 1cc and detecting over 40 specific gases from the EPA's air toxics list with 10-100 part-per-billion sensitivity. This device requires a high-efficiency preconcentrator, a multi-valve sampling system, and an integrated vacuum pump. The transport and surface interactions of microscale samples are being explored. Deposited thin-film coatings for corrosion protection and micromolding using advanced milling techniques are candidate approaches to micropackaging here along with microassembly techniques at the chip level.

Education

The multidisciplinary nature of this research is an ideal basis for making a significant impact on engineering education. At the high-school level, the Center is developing a set of teaching aids using MEMS to illustrate basic principles in physics and chemistry along with their applications in health care and environmental monitoring. Working with science coordinators, summer training programs for teachers are facilitating delivery to the students, with the goal of significantly increasing the number of young people pursuing careers in science and engineering. These outreach activities include special efforts with underrepresented minority students, selected in part through a partnership with DAPCEP (the Detroit Area Pre-College Engineering Program). At the undergraduate and graduate university levels, the ability to mix students with different backgrounds in team-oriented research is, we believe, absolutely critical in training future engineers. A series of courses, facilitating an M.Eng. degree in integrated microsystems, is being developed jointly by all three partnering universities. These courses involve extensive multimedia use and shared virtual laboratory experiences facilitated via distance learning technology. The courses will be fine-tuned across Michigan and then offered nationally. On-going seminars are being shared across campuses and industrial sites that highlight the pervasive societal implications of these microsystems along with technical advances.

|

| An integrated gas chromatograph for an environmental monitoring microsystem. |

Industrial Collaboration/Technology Transfer

Solving societal problems requires that technical developments be applied in products. Thus, technology transfer and industrial partnerships are critically important. An industrial partnership program has been established for the Center that involves leading companies in microelectronics, MEMS, and wireless communications, including companies from the automotive, environmental, and medical fields. These companies participate in the Executive Committee and Industrial Advisory Board of the Center, helping set directions and determine policies in both education and research. Named student scholarships and internships in industry as well as visiting industrial positions at the university are being used to facilitate technology transfer through personnel exchanges. Recognizing that the missing link in many technology transfer efforts is the ability to generate prototypes for evaluation by industry, the Center is also dedicating both personnel and facilities to producing such devices, ensuring that the results of its research are translated into products that benefit society.

Facilities

The Center makes use of state-of-the-art facilities for the fabrication of microsystems and associated devices, including the 14,000sf Class 10/100 Solid-State Fabrication Facility at the University of Michigan. This facility supports a full range of microstructure, device, and circuit fabrication techniques and has pioneered MEMS development for over two decades. Michigan State adds important facilities for new materials (e.g., diamond), while Michigan Tech adds capabilities for non-lithographic material processing and high-resolution micromilling. Very large scale micropower circuit fabrication is being carried out in facilities made available by our industrial partners. All three schools have extensive facilities for distance learning, which permit interactive networking of both research and educational efforts.

Center Configuration, Leadership, Team Structure

The Center involves faculty from most engineering disciplines as well as from computer science, chemistry, public health, and medicine. The efforts of these faculty members are focused by the research testbeds mentioned above. The Center Director and Deputy Director are from the University of Michigan, with Associate Directors from Michigan State and Michigan Tech. These individuals, together with the Administrative Director, the Associate Director for Industrial Programs, the Associate Director for Education, and the research thrust leaders, form the Management Committee for the Center. The Center Director reports directly to the Dean of Engineering.

![]()

Center Headquarters

Center for Wireless Integrated MicroSystems

The University of Michigan

2401 EECS Building

1301 Beal Avenue

Ann Arbor, MI 48109-2122

Homepage: http://www.wimserc.org/

Center Director: Dr. Kensall D. Wise

(734) 764-3346 · wise@eecs.umich.edu

Deputy Director: Dr. Khalil Najafi

(734) 763-6650 · najafi@engin.umich.edu

Administrative Director: Ms. Karen Richardson

(734) 647-1779 · karenr@eecs.umich.edu

NSF 00-137r