Center for Power Electronics Systems

Virginia Polytechnic Institute and State University (lead institution)

![]()

Changing the way electricity is used

| A National Science Foundation Engineering Research Center since 1998 |

![]()

|

Partner Institutions:

|

Throughout the world, electric power is used at an average rate of 12 billion kilowatts every hour of every day of every year. With few exceptions, the majority of this electrical power is not used in the form in which it was initially produced. Rather, it is re-processed to provide the type of power needed in the technology that is being employed. Power electronics is the engineering discipline that is utilized when converting electrical power from one form to another.

In terms of commerce, the impact of power electronics is huge. Sales of power electronics equipment exceed $60 billion each year and affect another $1 trillion in hardware electronics sales. The prospect of improvements in the technology of such a dynamic market is exciting. Industrial firms could introduce products that are more powerful, more dependable, more durable, smaller in size, lighter in weight, and less costly to the consumer.

The impact of power electronics is perhaps equally striking in terms of our environment. Power electronics systems are expected to control up to 80 percent of all electricity used by the year 2010. With the improvements in power electronics technology that the Center for Power Electronics Systems (CPES) has planned, the U.S. will be able to reduce its energy consumption by 30 percent.

|

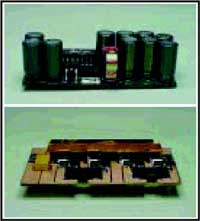

| The new technique presents a new topology for building voltage. Top: A conventional voltage regulator. Bottom: The new CPES QSW VRM. |

Recognizing the tremendous challenges involved in realizing these types of improvements in power electronics technology, five universities and more than 80 corporations joined forces in 1998 to create CPES. Our vision is both ambitious and achievable: we will provide the United States with the capabilities necessary to become a world leader in power electronics.

In order to achieve our vision, we developed a ten-year program centered on an integrated systems approach to standardize power electronics components and packaging techniques in the form of highly Integrated Power Electronics Modules (IPEMs). The IPEM approach makes possible increased levels of integration in the components that comprise a power electronics system: devices, circuits, controls, sensors, and actuators. These components are integrated into standardized manufacturable subassemblies and modules which, in turn, are customized for particular applications.

Our program includes four primary goals:

- Develop IPEM-based power electronics processes using an integrated systems approach; improve the quality, reliability, and cost-effectiveness of power electronics systems; and reduce both the time and effort associated with design cycles for systems application

- Explore viable and innovative opportunities for industrial applications and demonstrate these opportunities in practice via demonstrative programs

- Train future leaders by developing innovative power electronics systems-oriented curricula and approaches to foster interdisciplinary learning

- Share the knowledge gained by CPES initiatives through active outreach programs and industrial affiliate programs.

Research

Our program for research and technology development relies heavily on participation by industry. The three major thrusts of this program, along with their associated subthrusts, are designed to cover several areas of technology development and their applications. Within the first thrust area, Demonstrative Programs, we have implemented two initiatives to demonstrate the viability of the technology being developed: (1) Distributed Power Systems and (2) Motor Drives. Within the second thrust, Technology Development, we have identified three subthrusts: (1) Advanced Power Semiconductor Devices (APSD), (2) Integrated Packaging (IP), and (3) Control and Sensor Integration (CSI).

|

| A researcher at Rensselaer Polytechnic Institute uses a CGA stepper in advanced power device work. |

Integrated Power Electronic Module Synthesis (IPEMS) is a thrust unto itself to provide the system integration between the Demonstrative Programs and the Technology Development thrusts. IPEMS will also form a bridge between the technology thrust and the testbed subthrusts by facilitating IPEM development, with the specific objective of supporting the testbed applications.

The research prototypes for the demonstrative initiatives will be built and evaluated using a two-tier testbed approach. The first tier takes place in a university-based experimental testbed, and the second tier takes place within an industrial setting. The goal of the first tier is to evaluate "proof-of-concept" prototypes. At the second tier, our goal is to determine the feasibility and value for commercialization of existing applications.

Education

Our education and outreach program represents an important element of CPES's overall mission. Training our nation's future power electronics engineers is a role we take very seriously. In the U.S. today, more than 90 percent of the practicing engineers in the power electronics industry are trained while on the job. Lacking appropriate theoretical background in power electronics, today's engineers are severely hampered in their ability to advance and apply state-of-the-art technology.

Our education and outreach program consists of six components: (1) curriculum development and collaboration; (2) academic exchange and visitor programs; (3) undergraduate student research; (4) educational outreach to industry programs; (5) recruitment and retention of students from underrepresented populations; and (6) our high school program.

Goals of the education and outreach program include the following:

- Designing a multi-disciplinary power electronics systems curriculum that is relevant, timely, and focuses on developing students' problem-solving skills;

- Providing students with a comprehensive understanding of industrial perspectives as well as opportunities to work with industry on research and design projects;

- Utilizing existing strengths at individual CPES campuses and making them available and easily accessible to all CPES students during their academic career;

- Encouraging students from underrepresented populations to successfully pursue careers in power electronics;

- Familiarizing high school students, as well as undergraduate students, with power electronics technology as an academic option

- Providing practicing engineers with a wide array of short courses, seminars, and lifelong learning opportunities that are relevant to their particular needs.

Industrial Collaboration and Technology Transfer

The CPES Industrial Partners Program is the base from which we are able to bring our vision to reality. Our industrial partners' interests span a broad spectrum of technical areas, including semiconductor devices, control ICs, power electronics packaging, power modules (power supplies), distributed power systems, high-performance drives, low-cost packaged drives, and system manufacturers.

We rely heavily on the active participation of our industrial partners. The objectives of our Industrial Partners Program are twofold; our partners (1) provide guidance in our education, outreach, and technology transfer initiatives, and (2) work with us to explore emerging technologies and applications through both collaborative research and our demonstrative testbed programs.

Our Industrial Partners Program offers different types of membership. Member benefits vary according to the type of membership, but include a combination of the following:

- intellectual property rights

- an opportunity to influence CPES's programs through participation on CPES's Industry Advisory Board

- the option to establish a graduate fellowship and to select the area of research

- rapid access to all research data generated by CPES

- access to and participation in all CPES technology transfer initiatives in education, outreach, and industrial collaboration

- a direct and continuous link with CPES faculty and students.

Our Industry Advisory Board (IAB) is the mechanism through which industry provides counsel and guidance to CPES. The IAB, whose members serve two-year terms, is composed of one representative from each Principal Member of our Industrial Partners Program and representatives from 20 percent of our Associate Members.

Intellectual properties is one of the key benefits for Principal Members. Our Principal Members have royalty-free, non-commercial use of CPES-generated intellectual properties and the right to review publications for patentable materials. They also have the exclusive option to negotiate royalty-bearing licenses for commercial use.

CPES has established several university/industry exchange initiatives, including our (1) Graduate Student Industrial Fellowship Program, (2) Graduate Student Industrial Internship Program, and (3) Industry Residence Program. Coupled with our professional short courses, technical seminars, and distance learning programs all of which are geared for practicing engineers we work to maximize both interaction and the flow of information between industry and academia.

Center Configuration, Leadership, Team Structure

A major strength of CPES is its ability to use a wealth of existing resources and industrial collaboration. Virginia Tech, the University of Wisconsin-Madison, and Rensselaer Polytechnic Institute are the nation's leaders in power electronics and advanced power semiconductor materials and devices. These three universities have combined forces with North Carolina A&T University and the University of Puerto Rico-Mayagüez, which are institutions with solid reputations in the quality of their undergraduate engineering programs as well as their power electronics and related research.

Virginia Tech expertise involves high-frequency power conversion devices and circuit technologies, power electronics packaging, and systems integration. University of Wisconsin-Madison expertise involves industrial and utility-grade power conversion, electric machines and motor drives, and industrial controls. Expertise at RPI involves novel discrete power semiconductor materials, process techniques, power devices, and smart power ICs. North Carolina A&T expertise involves nonlinear control, neural networks, and fuzzy logic-based intelligent control; and expertise at the University of Puerto Rico-Mayagüez involves controls and electric machines.

![]()

Center Headquarters

Center for Power Electronics Systems

Virginia Polytechnic Institute and State University

657 Whittemore Hall (0179)

Blacksburg, VA 24061

Tel (540) 231-2267 · Fax (540) 231-6390

Homepage: http://www.cpes.vt.edu

Center Director: Dr. Fred C. Lee

(540) 231-4536 · fclee@vt.edu

Deputy Director: Dr. Dushan Boroyevich

(540) 231-4381 · dushan@vt.edu

Administrative Director: Ms. Ann Craig

(540) 231-2059 · annc@vt.edu

NSF 00-137u