Illinois Institute of Technology

A National Science Foundation Industry/University Cooperative Research Center since 2001

Partner Institutions:

- IIT Research Institute

- Los Alamos National Laboratory

- National Institute of Standards and Technology

Application of new thermal processing technology will improve quality and reduce costs for industry

|

Center Mission and Rationale

Thermal processing of materials is an essential part of most manufacturing processes. The TPT Center was established to advance the technology of thermal processing of materials. The main objectives of the Center are to:

- Conduct basic research and related developmental activities for the use of thermal processing technology in materials processing and manufacturing

- Provide timely and effective technology transfer between the Center and its industrial participants

- Promote education and training in thermal processing technology.

|

Research Program

Faculty and students from the departments of mechanical, materials, and aerospace engineering conduct research for the TPTC in six major areas: ferrous metals, non-ferrous metals, ceramics, powder materials, modeling and simulation, and sensors and controls.

|

The Center's milestone achievements include:

- Award of a State of Illinois Technology challenge grant to support the Center

- Award of a Center for Heat Treat Excellence project on distortion of heat treated parts

- $1.25M donation for research infrastructure development.

|

The Center has exceptional facilities and equipment for thermal processing and characterization of materials. The equipment available includes:

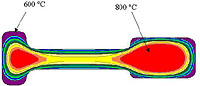

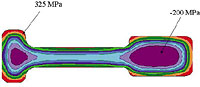

- Gleeble System 3500

- Scanning and Transmission electron microscopes

- X-ray diffractometer

- Controlled atmosphere integral quench furnace

- Eight gas furnace atmosphere analyzer

- 1800°C vacuum furnace

- Cryotreater

- Coordinate measuring machines

- Dilatometer

- Endothermic gas generator

- Quench tank with heater

- Quench press

- 1.5 KW laser with machining workstations

Center Headquarters

Thermal Processing Technology Center

Armour College of Engineering

Illinois Institute of Technology

10 W 32nd Street

Chicago, IL 60616

Tel (312) 567-3056 * Fax (312) 567-8875

Homepage: mmae.iit.edu/~tptc/

Center Director: Professor Philip Nash

nash@iit.edu

Center Associate Director: Dr. Richard Johnson

rjohnson@iitri.org

Center Evaluator: Dr. E. Geisler

(312) 567-6157 * geisler@iit.edu

NSF 01-168kk