Particulate Materials Center

The Pennsylvania State University

A National Science Foundation Industry/University

Cooperative Research Center since 1995

Improving the processes underlying the production of powders and manufacturing with particulate materials

|

Center Mission and Rationale

Powder synthesis, dispersion, grinding, agglomeration, and sintering are

common unit operations in many particulate-based materials manufacturing

industries such as protective coatings; composites; photography; cosmetics;

pharmaceuticals; electronic, magnetic, optical, and structural applications;

and others. Companies producing powders or manufacturing finished particulate

materials share a common need for improved process consistency, efficiency,

and reliability. The Particulate Materials Center was established to assist

industry in achieving this goal by research into various stages of particulate

materials manufacturing and processing, establishing educational programs

for undergraduate and graduate students, and creating knowledge-transfer

opportunities for industry. The research program seeks to improve particulate-based

manufacturing by: 1) developing new techniques for characterizing particle

behavior at all levels of manufacture, 2) developing computational tools

for efficient process simulation and evaluation, and 3) implementing these

methods to obtain advanced process understanding and improved product

manufacture. Information is transferred to member companies through biannual

meetings, visits, workshops, short courses, and future employees. The

highly interdisciplinary PMC faculty appointments span the Colleges of

Agricultural Sciences, Earth and Mineral Sciences, Engineering, Science,

and Penn State's Interdisciplinary Materials Research Institute.

|

Research Program

The seven primary PMC research thrusts are:

- Colloidal and Interfacial Chemistry -- Overall objectives are to establish methods for assessment and prediction of chemical-mechanical polishing behavior; and to develop computational codes for prediction of colloid behavior, including metals, polymers and complex metal oxides and hydroxides used for electronic applications. Thermodynamic, as well as kinetic, rate effects are investigated.

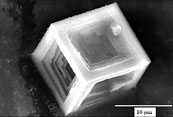

- Electrophoretic Deposition -- Multilayer processing is vital to applications with electroceramic and electrooptic materials. Electrophoretic deposition (EPD) is an innovative submicron technique offering significant advantages over primitive screen printing methods. Significant EPD technology includes: dispersion of nanosized particles in non-aqueous solvents with zeta potentials as high as 60 to 100 mV; and development of apparatus to obtain prototyping tapes with a continuous process. One of the thrusts is the development of a fundamental understanding in depositing nanoparticulates.

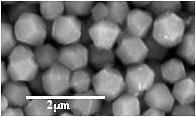

- Nanomaterials -- The overarching goal is to produce non-agglomerated nanocrystalline ceramic powders that have superior dispersibility and sinterability processability over the presently available agglomerated varieties. Two major sources of agglomeration have been researched: 1) chemical interactions between particle surfaces, and 2) dissolution of ions from a particle surface. Research relates nanopowder solubility and surface chemistry to mechanical attributes such as strength, size, and structure of agglomerates. Innovative deaggregation methods developed by PMC projects are patent pending.

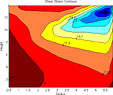

- Powder Mechanics -- Reliable, rapid, real-time and automated test devices are being developed. Principle research objectives are: to augment powder storage, flow, and compaction processes; to develop and validate a PC-based powder compression model; and, to develop correlations between powder deposition methods, constitutive parameters, and compact quality. Prediction of new formulation performance and minimization of defects are determined. An efficient version of the finite element model is being developed for a PC environment with potential to become a benchtop analytical tool.

- Sinter Systems -- The ultimate goal is to develop tools that will reduce pressing defects and increase the efficiency of powder pressing operations. Predictive software is developed that incorporates all stages of the press and sinter operation, from the selection and blending of powder, binder, plasticizers and lubricants, through the quick, accurate design of tooling and the evaluation of dimensional changes that occur during sintering.

- Solution Synthesis -- Large-scale solution synthesis of monodisperse metal and metal oxide powders is developed. Research includes: development of technologically useful materials through post-synthesis processing of gel-sol-derived powders and pigments; synthesis of a wide variety of simple and complex oxides; and utilization of elevated temperatures to enhance particle formation rate. The effects of additives on particle shape, particle size, and crystal phase modifiers are investigated.

- Spray Formation -- Particle production processes are investigated through which a solution or slurry is atomized into discrete aerosol droplets and subsequently transported through a time/temperature/atmosphere-regulated environment. Goals are: to improve the properties of powders used in powder pressing and other processing operations; and to correlate slurry parameters and spray drying conditions to the properties of spray dried particles. Advancements include a new effort to synthesize submicron and nanoscale organic and inorganic particles using a variety of approaches, in some cases forming spherical particles from solution precursors.

|

PMC Outreach

Particle Characterization Laboratory (PCL) -- The PCL is a state-of-the-art

user facility for characterization facility for of routine and complex

powders, characterization, industrial short-course training, and student

education. The facility was established to assist industrial partners

and to support PMC research activities. The PCL is supplemented by equipment

manufacturers' equipment donations supporting PMC research and education.

Specialized characterization is provided via additional extensive materials

characterization facilities on campus.

|

Education -- Industrial members' dues go directly to support M.S.- and Ph.D.-level research projects. The Center also supports an Undergraduate Research Fellowship program through which students work on research projects generated by industrial sponsors. PMC biennially organizes the Fine Powder Processing International Conference, designed to educate the world materials community about powder processing and manufacturing issues.

Knowledge Transfer -- The PMC regularly organizes short courses, seminars, and conferences in topical areas consistent with the research program and member interests. Program topics include Applied Powder Mechanics, Colloidal and Interfacial Chemistry, Powder Characterization, and others under development. Programs can be tailored for in-house use for interested companies.

Center Headquarters

Particulate Materials Center

The Pennsylvania State University

249 Materials Research Institute

University Park, PA 16802

Tel (814) 863-6156 * Fax (814) 863-9704

Homepage: www.mri.psu.edu/centers/pmc/

Center Director: Dr. James H. Adair

jadair@mrl.psu.edu

Center Staff Assistant: Ms. Antoinette Love

ael10@psu.edu

Center Evaluator: Mr. Stephen L. McGregor

(814) 865-9519 * slm5@psu.edu

NSF 01-168m