Center for Dielectric Studies (CDS)

Pennsylvania State University (lead institution) and University of Missouri at Rolla

A National Science Foundation Industry/University Cooperative Research Center since 1983

An improved understanding of dielectric materials will lead to the development of advanced devices for electronic technology

|

Center Mission and Rationale

Research projects at the Center for Dielectric Studies (CDS) aim to improve the basic understanding of the synthesis, processing, and properties of dielectric materials and the electrode metallizations for electronic devices. These devices include: capacitors, microwave components, hybrid microcircuits, thermistors, packages, multichip modules, and thin-film dielectrics. CDS member companies are a mix of material suppliers, device manufacturers, and final users of electronic devices. Having a vertically integrated set of sponsors helps CDS to maintain focus on problems relevant to industry.

The overall CDS research program is almost equally funded by membership fees, State and Federal grants, and industry enhancement projects.

Research Program

The Center's research thrust areas are:

- Synthesis and Processing, including: rate-controlled sintering (smart processing); rate-controlled binder burnout; electrophoretic deposition; hydrothermal barium titanate sintering; low-temperature barium titanate sintering

- Capacitor Dielectrics and Reliability, including: reliability of thin layers; dielectric breakdown relationships; electrode-dielectric interfaces; fine particle/fine grain properties; nonlinear dielectric properties; high-energy storage dielectrics

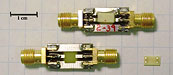

- Microwave Dielectrics, including: electric field tunable dielectrics; pyrochlore dielectrics (low fire); electromagnetic shielding materials; strip line materials and filters

- Packaging Dielectrics, including: polymer ceramic composites; low-permittivity materials; (permittivity < 2); multichip modules (MCMC)

- Multilayer Co-fire Dielectrics, including: low temperature co-fire (LTCC); new types of co-fire metallization; integration of high- and low-permittivity materials; integration of varistors for overvoltage protection; integrated multilayer filters

- Thin Film Dielectrics, including: electrochemical barium titanate films; ferroelectric high-permittivity films; PZT, bismuth titanate, barium strontium titanate, barium titanate, strontium titanate; laser-ablated films, bismuth pyrochlore; multitarget magnetron and multi-ion beam reaction sputtering; sol-gel films

- High Temperature Dielectrics, including: passive components for temperatures > 250*C; capacitor materials for temperatures reaching 600*C

- Pulse Power Capacitors, including: dielectric design, modeling, and device engineering.

- Dielectric Resonator Antennae, for blue tooth communication, FDTD-modeling, and microwave field analysis.

|

Facilities

CDS is housed in the Pennsylvania State University's 70,000 square-foot Materials Research Laboratory, which is designed for the needs of interdisciplinary materials research. The laboratory maintains central facilities common to various types of research and is capable of conducting scanning electron microscopy, environmental scanning electron microscopy, transmission electron microscopy, state-of-the-art x-ray diffraction, thermal analysis, and wet chemical analysis. University of Missouri-Rolla has complementary facilities

Processing and Synthesis

Powder synthesis and processing can be carried out with ball mills, vibration mills, and attritor mills, and a three-roll mill is available to mix pastes and inks. CDS's multilayer capabilities include tape casting, screen printing, and multilayer lamination. Firing of hybrids can be done in either an IR or resistance-heated belt furnace.

For processing research, CDS has a computer-controlled furnace room with controlled-atmosphere firing capabilities and a custom-designed, fast-fire furnace. CDS has made a rate-controlled sintering system for studying densification mechanisms in multilayer ceramics. A new automated furnace system for smart control of the binder burnout process is being constructed.

|

Measurements

CDS, both at Penn State University and the University of Missouri-Rolla, has collectively one of the most comprehensive electrical measurement facilities in the world for dielectric materials. Routine automated, multi-sample dielectric tests are carried out at temperatures ranging from that of liquid nitrogen to 200*C and for frequencies from 100 Hz to 10 MHz. CDS has written custom data analysis programs to extract dielectric properties from the electrical test data. CDS also designed high-temperature dielectric measuring equipment that operates at temperatures up to 1200*C. Specialized pulse power and breakdown characterization facilities exist for capacitors at the Rolla site.

Specialized microwave and RF spectrum analyzers available to CDS can measure up to 26 GHz, while a low frequency FFT dielectric spectrometer is capable of measuring to 1.0 milliHz. Multi-sample dielectric reliability tests are set up for computer-automated data collection.

Special Center Activities

At CDS, graduate students and postdoctoral researchers are active participants in the Center's basic and applied research programs. Three students have assisted in CDS research through the Women, Minority, and Disabled High School and Undergraduate Engineering Research Assistants program. To date, a total of 19 students have obtained Ph.D. degrees through the CDS program and 30 students have earned Master's degrees. Approximately 15 students and 14 faculty members currently participate in the Center's programs. Some students supported by fellowships elect to conduct research in the Center, which provides financial support for these research projects.

The Center holds symposia on topics of interest to its members, including such subjects as powder analysis methods, reliability of ceramic devices, improvement of multilayer capacitor reliability, multilayer ceramic reliability, and power electronics.

To provide broad technology transfer to its sponsors' technical staffs, CDS faculty are also available to conduct one-day seminars at participating company sites. In addition, CDS strongly encourages its member companies to send an R&D representative to spend time at the Center's lab and believes that this interaction is the most effective method of technology and knowledge transfer from academe to industry. The Center will provide logistical support for visits ranging from one week to one year.

Center Headquarters

Center for Dielectric Studies

Materials Research Laboratory

The Pennsylvania State University

University Park, PA 16802

Tel (814) 863-1328 * Fax (814) 865-8126

Homepage: www.mri.psu.edu/Centers/cds

Center Director: Dr. Clive A. Randall

car4@psu.edu

Associate Director: Michael T. Lanagan

mxl46@psu.edu

Associate Director (UM-R): Harlan Anderson

311 Materials Research Center

University of Missouri-Rolla

Rolla, MO 65409

Tel (573) 341-4886 * Fax (573) 341-6165

harlanua@umr.edu

Center Evaluator: Donna M. Dengler

(703) 716-7448 * ddengler@erols.com

NSF 01-168n